12

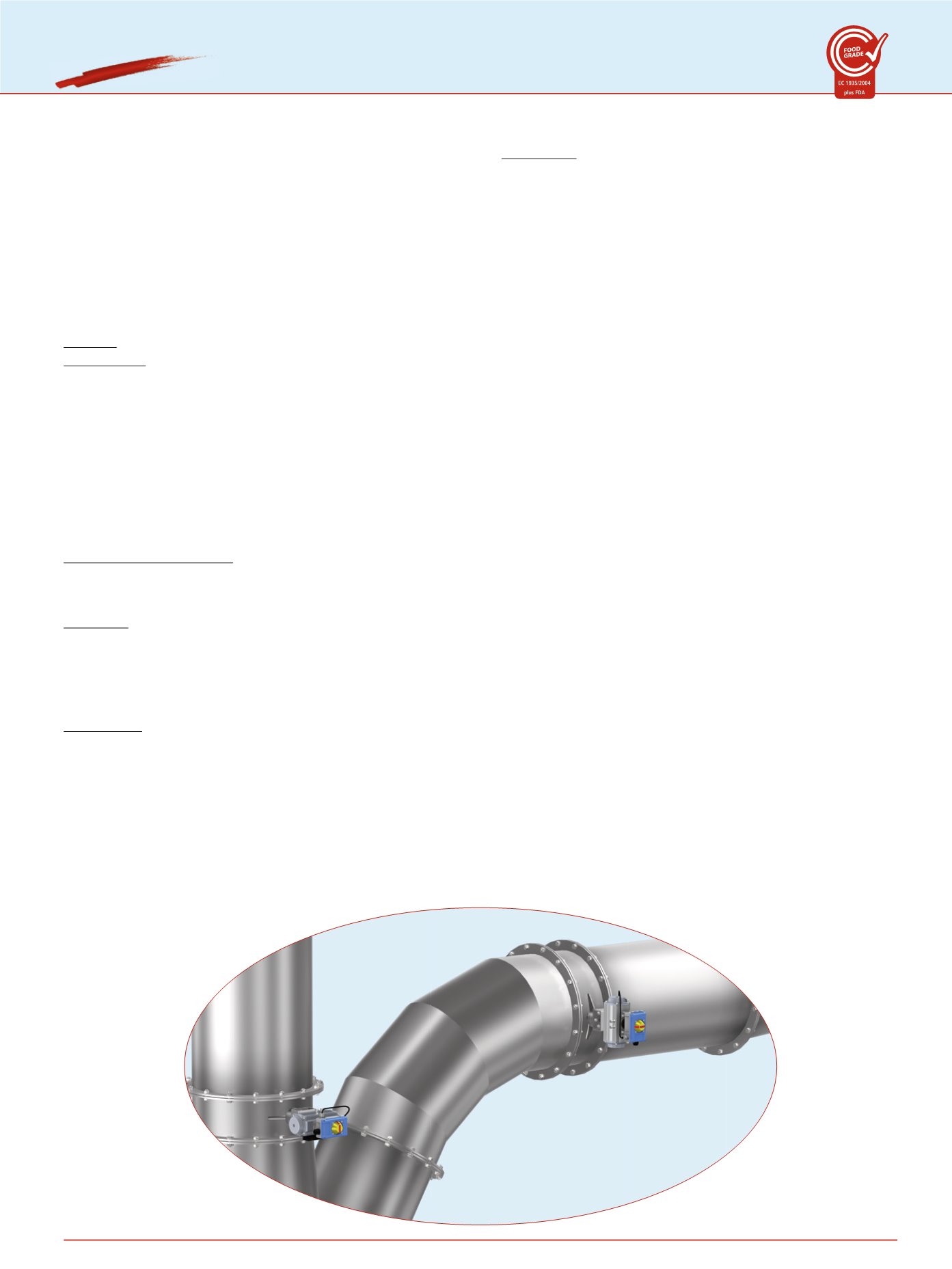

JACOB flange system with 10 mm lip and flanges acc. to DIN 24154, T2

150

DN 350–1250 mm:

With loose flanges as standard.

Stainless steel: With galvanized loose flanges as standard.

Surcharge for loose flanges made of stainless steel.

Surface CrNiblasted.

DN 900–1250 mm

with loose flanges are recommended only for air applications.

Also available with fixed flanges instead of loose flanges – on request.

Earthing lugs on request.

DN 1400–1600 mm

in 3 mm wall thickness with welded on flanges as standard.

Stainless steel: Surface pickled and passivated.

Other diameters on request.

Materials:

Mild steel: material DC 04 (ST 1403), DC 01 (ST 1203), S 235 (ST 37)

Powder coating:

Powdercoated inside and outside (DN 60–630 mm).

The powdercoating is electrostatically conductive.

All of the raw materials used in our standard powdercoating, coloured pebble grey,

similar to RAL 7032, comply with the FDA requirements for direct contact with food

(e.g. regulation 21 CFR175.300 “Resinous and polymeric coatings”).

Coating thickness on the outside: Powdercoating as primer with an average layer

thickness of 55 μm.

Temperature resistance: Powdercoating properties are practically stable between

60 °C and +120 °C.

Layer thickness on the inside: The surface is optically covered. The coating on the

inside is only applied to provide temporary corrosion protection in storage and

transport conditions until the products have been installed.

Priming (Sprayed primer coating):

Inner and outer priming, coloured pebble grey, similar to RAL 7032.

Primed surface finish is identified in the catalogue. Diameters > 630 mm are primed in

the standard quality. Powder coating also available on request.

Final coating for modular pipework systems

(RAL colour chart, external, on request):

More than 3 000 colour and effect variations; special colours and structured coatings

up to 630 mm diameter available powder coated, on request.

Total thickness of coating (including primer): Approximately 80 μm.

Electrical conductivity available on request, at a surcharge.

Alternatively spray painted, on request.

Hot galvanising acc. to DIN EN ISO 1461:

Average coating thickness (minimum value) depends on the thickness of the steel:

< 1.5 mm: 45 μm,

≥

1.5 mm to

≤

3 mm: 55 μm, > 3 mm to

≤

6 mm: 70 μm.

Withstand temperature up to 200 °C.

Galvanic method according to DIN 50961. Coating thickness approx. 10 μm.

Withstand temperature up to 120 °C.

Stainless steel: Material 1.4301, AISI 304 (X5CrNi1810)

surface CrNiblasted, temperature resistance up to 300 °C.

JACOB’s stainlesssteel products made of 1.4301, 1.4571 or comparable grade steel

comply with the criteria outlined in the “EU guidelines on metals and alloys used

as food contact materials” (13.02.2002) issued by the Council of Europe. They are

suitable and approved for use in contact with food, depending on the corrosiveness of

the medium.

As standard the listed components are made of stainless steel with loose flanges out of

hotdip galvanized standard steel.

There is a surcharge for loose flanges made of stainless steel.

Diameter DN 350– 1250 mm in 2 mm wall thickness with loose flanges, standard.

> DN 1250 mm with weldedon flanges.

Stainless steel > DN 1250 mm: Surface pickled and passivated.

Special versions in material 1.4571, AISI 316Ti (X6CrNiMoTi17122) with flanges made

of stainless steel, surface pickled and passivated, available on request.

Wall thicknesses:

Pipes:

1.5 mm usable for ventilation systems up to 100 mbar gauge pressure.

2 mm pipes up to diameter 800, shock explosion proof up to 3 bar.

3 mm pipes on request, 3 mm stainless steel only available with weldedon flanges.

Components:

1.5 mm, 2 mm and 3 mm wall thickness.

3 mm on request, 3 mm stainless steel only available with weldedon flanges.

Tolerances:

Pipe diameter and roundness acc. to DIN EN 102961.

Lengths and angles acc. to DIN ISO 27681, tolerance class V.

Exclusions: Segments and spouts with inclination, angle tolerance = ±1°.

Shock explosion proof up to 3 bar overpressure:

Pipes

2 mm thick up to Ø 800 mm

Segments 5° up to 45°

2 mm thick up to Ø 800 mm

Bends 30° up to 90°

2 mm thick up to Ø 800 mm

Tpieces

2 mm thick up to Ø 500 mm, 3 mm thick up to Ø 800 mm

Forks 30° and 45°

2 mm thick up to Ø 500 mm, 3 mm thick up to Ø 630 mm

Conepieces

2 mm thick up to Ø 630 mm, 3 mm thick up to Ø 800 mm

Symmetrical forks 60°

2 mm thick up to Ø 500 mm, 3 mm thick up to Ø 800 mm

Symmetrical forks 90°

3 mm thick up to Ø 630 mm

Throttle valves over Ø 300 mm have not yet been tested to date by an independent

specialist institute on shock explosion proof quality; but internal tests with water

pressure resulted in sufficient strength for a diameter up to 630 mm with 2 mm

wall thickness. Throttle valves over Ø 300 mm are only shock explosion proof to the

outside, but not inside the pipe system.

Shockexplosion proof cleaning pipes are not available, alternatively inspection pipes

(diameter of opening 115 mm) up to a pipe diameter of 630 mm could be delivered as

special versions.